KES System

The KES system is the first metal joinery hardware construction method for wood-built structures developed and standardized in Japan.Since the completion of the prototype in 1974, repeated improvements have been made and patents have been acquired in various countries around the world.Developed with the mission to “protect the lives of families and properties,” the KES system has been applied to a wide-range of wood-built structures from homes to large-scale and mid-to-high-rise public structures.

Metal joints with astounding strength and freedom of application

Joint areas have been considered to be the major weakness of wood-built structures.The conventional timber framework method required processing of joints such as a “mortise” and “tenon,” and commonly involved cutting into structurally important materials such as columns and beams.This resulted in weakening the original strength of the timber.

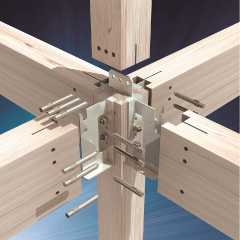

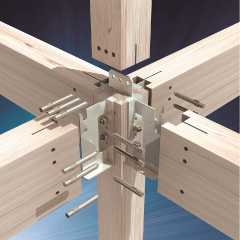

The KES system has thoroughly enhanced this major weakness through use of original metal joints and has achieved astounding strength.This has enabled freedom in design such as for large spaces and large spans which was difficult to realize with the conventional timber framework method.The KES system’s original metal joints have their own “hook” and “torsel” that are not found on other metal joints. These parts serve to increase resilience and workability.

Superior force bearing and durability performance as an absolute future measure

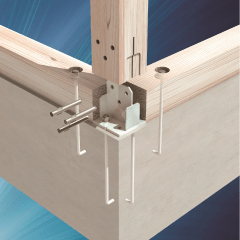

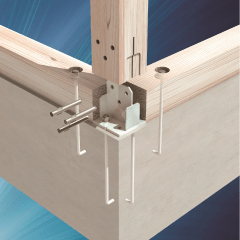

With conventional construction methods, columns are placed on top of the groundsill with the potential for compressive strain and cracking to occur to the groundsill if a large load is applied.Similar to columns in Japan’s ancient shrines and temples, the KES system involves fastening columns directly to the foundation which disperses the force of an earthquake to the foundation.

This protects the building against disasters and deterioration over the long-term.

The KES system’s proven durability during earthquakes

The N residence, which is a three-story house built with the KES system, was located in Nada District of Kobe City where damage was heaviest during the Hanshin-Awaji Earthquake.Precious lives and property was protected in a region where even a three-story reinforced concrete condominium collapsed.

Kurikoma General Branch Office located in Kurihara City, Miyagi Prefecture which was built with the KES system was undamaged during the 2008 Iwate-Miyagi Inland Earthquake which registered an upper 6 on the Japanese intensity scale of 7.The building also withstood a seismic intensity of 7 registered during the 2011 East Japan Earthquake and was used as the local disaster headquarters.

* We would like to offer our sincere sympathies to those who were affected by the disasters.

N residence

Kurikoma General Branch Office

Kurikoma General Branch Office immediately after the East Japan Earthquake

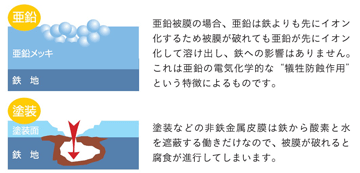

Hot-dip zinc galvanizing that is rust-resistant and dramatically increases the durability of metal joints

All metallic joints used in the KES system are hot-dip zinc galvanized for rust resistance. Joints are galvanized with zinc coating masses of more than 500g/㎡ which is the highest level in the JIS standard, and have anti-rust effect which is higher than the rust resistance applied to electrical power transmission towers (350g/㎡).Conventional cation electro-deposition coating used indoors in a coastal region will allow rust to form after roughly 50 years, while hot-dip galvanization to 500g/㎡ has a fatigue life endurance of more than 173 years.

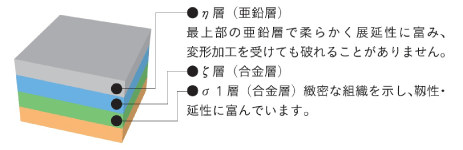

Superior characteristics of hot-dip zinc galvanization

Zinc coating is formed by alloy-reaction of steel and zinc. Therefore the coat has strong adhesion and does not peel or crack under normal use.

As the industry forerunner in acquiring the “S Mark,” the KES system boasts reliable quality.

Since the Hanshin Earthquake, the challenge to raise the load-bearing strength of joints that support the integrity of homes has become a matter of urgency. Presently, the load-bearing strength of each structural framework element must be clearly indicated.The metal joints used in the KES system have acquired the government approved “S Mark certification” at an early stage ahead of industry.Shelter joints provide reliable quality.Furthermore, all homes are covered by joint section insurance (special provision on product liability insurance) which provides greater peace of mind to customers.

What is “S Mark”?

The S Mark is a certification by the Japan Housing and Wood Technology Center. Performance indications which have been inconsistent between companies are evaluated and accredited by this third party.

In ensuring safety, Shelter is particular about even a single nail or drift-pin

To achieve high performance, the nails connecting walls and floors, and the drift-pins connecting fittings, beams, and columns are important elements. With the KES system, strict quality control is performed to ensure highly reliable construction.