COOL WOOD

Fire-resistant wood material COOL WOOD

COOL WOOD developed by Shelter is a fire-resistant wood material which utilizes gypsum board for the fire stoppage layer.

The material is easy to process and can be manufactured with various types of wood according to the design and cost. The wood appearance of columns and beams imparts a warm feeling to the building’s finish.

◎One-hour fire-proof structural specifications (columns, beams, outside walls)

◎Two-hour fire-proof structural specifications (columns, beams, partition walls, outside walls, floors)

◎Three-hour fire-proof structural specifications (columns, beams)

Patents acquired in Japan, Canada, and Switzerland. Minister of Land, Infrastructure, Transport and Tourism (Japan) certified.

【Features】

・All tree species can be chosen for the surface layer

・JAS materials, incombustible, quasi-incombustible, flame-retardant treated lumber can also be used

・Convenience of processing (use only materials in circulation, special tools unnecessary)

Fire-proof wood structure technology

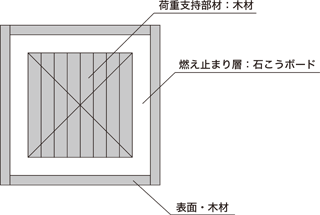

【Three-layer structure】(Patent No. 4359275)

1.The internal load bearing section is wood

2.The intermediary fire stoppage layer is gypsum board

3.The surface material is wood (columns, beams)

Fire-proof performance test

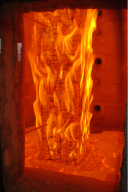

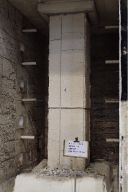

Fire-proof performance tests are performed to acquire accreditation from the Minister of Land, Infrastructure, Transport and Tourism.For the three-hour fire-proof performance test, a load was applied to the test material and burned for three hours in a furnace at temperatures exceeding 1000℃. After three hours, the test material is left inside the oven with the furnace closed for an additional nine hours.12 hours after starting the test, the oven door is opened, the gypsum covering on the test material is peeled off, and the surface of the load bearing wood without carbonization marks (burns) is checked.The purpose of this test is to confirm that in the event of a fire, even under conditions when fire extinguishing cannot be performed for a long period of time, the test material will naturally extinguish and not result in the building’s collapse.

①Test material is produced

②Material placed inside furnace

③During combustion

④Test material after being naturally extinguished

⑤Internal inspection

左から、①試験体製作、②炉の中に設置、③燃焼中、④自然鎮火後の試験体、⑤内部確認。

Examples of application

Shelter Nanyo Hall

(Yamagata Prefectural Nanyo City Cultural Hall)

This cultural hall was built using plenty of locally-sourced Japanese cedar. With a capacity of 1403 seats, the hall is the world’s largest wooden concert hall.

【Construction Overview】

Design: Daiken Sekkei, Inc.

Construction: joint venture by Toda Corporation, Matsuda Co., Ltd., NAS Construction Co., Ltd.

Total floor area: 5,900.98㎡

Floors: One floor underground, three floors above ground

Fire zone: Article 22 zone of the City Planning Act

COOL WOOD specification: one-hour fire-proof (columns)

Kyoto Wood Hall

Kyoto’s first four-story building made only from wood. Uses 100% locally-grown Japanese cedar and hinoki cypress for structural materials.

【Construction Overview】

Design: Yu Architectural Design Office

Construction: Yoshimura Construction Co., Ltd., Takeuchi Koumuten Co., Ltd. (carpentry)

Total floor area: 754.50㎡

Floors: four floors above ground

Fire zone: Semi-fire zone

COOL WOOD specification: two-hour fire-proof (columns)

G Building Jiyugaoka 01 Annex B

Commercial facility opened in the center of Tokyo.Cedar columns and beams are left exposed to create a woody interior.

【Construction Overview】

Design: Klein Dytham Architecture + Fujita Corporation

Construction: Fujita Corporation

Total floor area:895.38㎡

Floors: Two floors underground (RC), three floors above ground (wood)

Fire zone: Semi-fire zone

COOL WOOD specification: one-hour fire-proof (columns, beams)

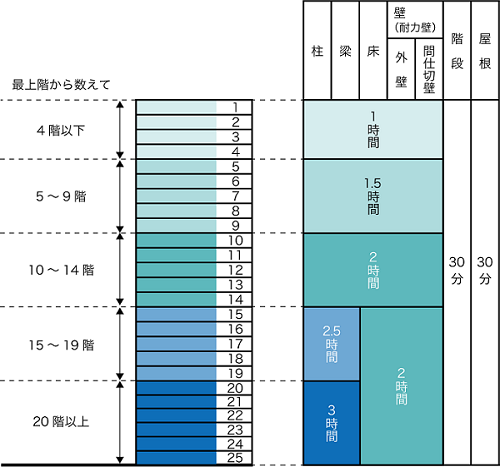

Japan’s first! Three-hour fire-proof certification acquired

Shelter was the first to acquire three-hour fire-proof accreditation from the Minister of Land, Infrastructure, Transport and Tourism in December 2017.

Wooden high-rise buildings have been built all over the world, but those built in Japan had been limited to 14 stories (two-hour fire-proof specifications).By realizing three-hour fire-proof specifications which is legally the longest fire-proofing specification, limitations on number of floors were lifted, making it possible for wood to be incorporated into high-rise buildings of 15 stories and higher which hitherto could only be built from steel or reinforced concrete.

Shelter is further developing its technology to realize “Timberized Cities” lined with a diversity of wooden buildings that are “fire-resistant and friendly to people and the environment.”

Fire-proof duration required according to number of floors and main structural materials

As high-rise buildings must consider evacuation time from the top floor, the required fire-proof duration of the bottom floor will become longer as the number of floors increases.

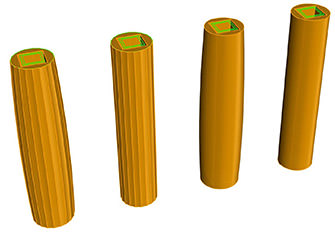

Round columns – a new design for fire-proof wood materials

“Cylindrical columns” which offers both fire-proofing and designing qualities can be produced with COOL WOOD.

Processing involving entasis (a convex body with a gentle curve) and fluting (longitudinal surface furrows) can also be applied.As these options require complex processing, they can only be manufactured employing Shelter’s 3D woodworking machines.Various designs such as polygonal shapes and curved surfaces can be achieved according to the designer’s imagination.

From left: entasis/fluting, fluting, entasis, straight

About intellectual property rights

Click on the following link for details on patents pertaining to COOL WOOD.

About Shelter-owned patent No. 4359275